Search

Fuelling the future

Backhoe loader manufacturers are developing hybrid or fully electric backhoe loaders, which significantly reduce or eliminate fuel consumption and emissions.

Going forward, digital technology will play a key role

Deepak Shetty, CEO and Managing Director, JCB India, speaks on the key demand drivers for backhoe loaders in India, and its dealership and product service

Going forward, digital technology will play a key role

Deepak Shetty, CEO and Managing Director, JCB India, speaks on the key demand drivers for backhoe loaders in India, and its dealership and product service.

The Versatile Workhorse

Telehandlers can perform a wide range of tasks in various industries.

Demand for reliable material handling products is fast growing

Deepak Shetty of JCB India speaks on the market for telehandlers in India

$5.13 Bn Opportunity!

Growing at a CAGR of 9.4 per cent, the Indian backhoe loader market is likely to touch $5.13 billion from $1.77 billion in 2021.

JCB machines are getting smarter

Innovation and Sustainability have always remained critical to our operations, and we continue to introduce products that significantly limit their impact on the environment. The JCB 19C-1E is the industry’s first fully-electric excavator in India and is integral to JCB’s ‘Road to Zero’ initiative, a programme that we have been working on for the past few years. The machine has been tested extensively and has various built-in features that enhance safety and performance. With Zero Emissions and low noise, this new machine is ideal for Infrastructure development in Urban Areas and Indoor working,” said Deepak Shetty, CEO and Managing Director, JCB India

JCB launches new range of CEV stage IV compliant wheeled CE

JCB India launched its all-new range of CEV Stage IV compliant wheeled construction equipment vehicles. The launch of these machines makes JCB India the first company in the industry to have brought in the CEV Stage IV emission standards across its range of wheeled machines.

JCB launches new range of CEV stage IV compliant wheeled CE

The range includes the 3DX Plus and the 4DX backhoe loaders, the VM117 soil compactor, the 530-70 and the 530-110 telehandlers with engines complying with the new emission norms. For bulk handling, three new wheeled loaders, the 433-4, the 437-4 and the 455-4 were also launched with new engines.

JCB’s range of CEV stage IV backhoe loaders

India’s leading manufacturer of earthmoving and construction equipment, JCB India flagged off its new range of CEV Stage IV backhoe loaders at its Headquarters at Ballabgarh (Delhi-NCR). The range includes the new 3DX Plus, the 3DX Xtra, the 3DX Super and the 4DX to meet a wide range of applications for customers.

JCB launches its range of CEV stage IV backhoe loaders

The range includes the new 3DX Plus, the 3DX Xtra, the 3DX Super & the 4DX to meet a wide range of applications for customers.

We are leveraging digital technology in our products and services: Jasmeet Singh

JCB has pioneered the integration of digital technology in its ‘Intelli’ series of construction equipment. Jasmeet Singh, AVP, Corporate Communications & Corporate Relations, JCB India, shares more.

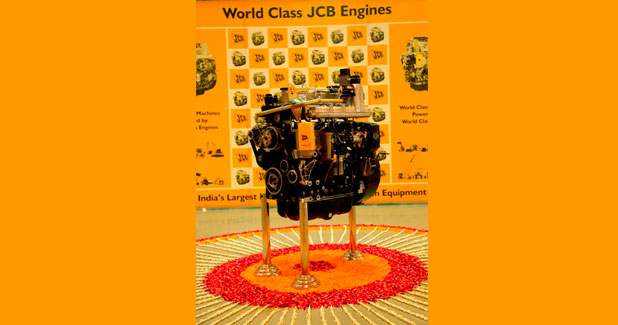

JCB ecoMAX engine

In 2011, JCB India inaugurated a world-class engine manufacturing facility in Delhi-NCR which is also the world's largest backhoe plant. In over six years, JCB has manufactured over 1,50,000 ecoMAX engines and machines fitted with these engines have been exported to over 90 countries.

Gearing up for the next level

Says Mathur, ?It is the government agencies who are asking for the implementation of Euro-V and VI (norms).

JCB India rolls out 100,000th ecoMAX

JCB India set a production landmark by rolling out its 100,000th JCB ecoMAX engine in its fifth year of production.

JCB India rolls out 100,000th ecoMAX engine

JCB India set a production landmark by rolling out its 100,000th JCB ecoMAX engine in its fifth year of production. The company started manufacturing its own range of engines in India in 2011.

Gaining Traction

With a major thrust on infrastructure development by the government, coupled with the ?Make in India? programme, the Indian telehandler industry is poised for an unprecedented and exponential growth.

backhoe loaders:flat Growth

Backhoe loaders are passing through a challenging time for the past few years. Market is registering a flat growth with some indications that it is shrinking.However, now there is optimism among the leading players in the backhoe industry

Intelligent Compaction

Performance and productivity remain key issues for compactor manufacturers, with firms keen to enhance output from their latest units. EQUIPMENT INDIA takes a peek into the features major OEMs have built in, in terms of improving machine

VMT860 Roller

The 9T tandem roller VMT 860 is designed to offer high productivity and reliability with maximum operating economy.

Maximising Output

Several key trends are emerging in the asphalt/soil compaction market where performance and productivity remain key issues. The OEMs are keen to maximise output from their latest units in terms of improving machine performance, O&M cost and operator safety and comfort.

Achieving Cost Efficiency

Cost efficiency is not only achieved through cleaner engines, but also through optimising the man-machine interface with a variety of machine control technologies, 'correcting' the usage patterns, and packaging solutions that take care of clients' business needs around project costs.

The government should award projects only after securing key sovereign clearances.

With the government planning for a major infrastructure boom in the North-Eastern states, we foresee a lot of potential for businesses to grow and flourish. The government plans to make investments in roads, railways, air connectivity, cyber and telecom connectivity and power in this region, says Amit Gossain, Vice President - Marketing and Business Development, JCB India. Excerpts of the interview.

JCB Steps up Engine Strategy Development

JCB forges a partnership with the Kohler-Lombardini Group, a leading global manufacturer to produce engines for its compact equipment.JCB has gone from being a new entrant in engine manufacturing to an innovative global producer with the first JCB engine rolling off the production line in the UK in November 2004.

JCB constantly keep upgrading the machine to meet the growing requirements.

The JCB backhoe loader continues to be the most widely used equipment in India and we constantly keep upgrading the machine to meet the growing requirements of our customers, says Vipin Sondhi, Managing Director and CEO, JCB India.

Customer satisfaction is the principal force guiding all JCB initiatives

JCB will continue to enter the market with revolutionary, fuel- efficient and world class products to meet the market and customer requirement, says Amit Gossain, EVP -Marketing, Business Development & Corporate Affairs, JCB India. Excerpts from the interview.

Bauma Breaks Records

A record 530,000 visitors from over 200 countries converged on the Messe Mnnchen exhibition centre between April 15 and 21. This, the 30th edition of bauma, broke all previous records for exhibitor numbers and exhibition space.

50,000th JCB Engine

JCB India has rolled out its 50,000th JCB engine at its Ballabgarh facility in India. In 2011, JCB launched its first domestically built world-class, fuel-efficient, state-of-the-art, BSIII, 16- valve diesel engine which is high in fuel efficiency.

Improving Cost-efficiency

Improvements in cost-efficiency, noise control, environmental design and ergonomics - the construction industry is facing such demands on many fronts. The good news is that not only the OEMs.

We will continue to strengthen our presence in wheel loader segment

Our entire range of world class attachments has met with a splendid response from our customers owing to their best-in-class features such as robust casing, higher operating weight that helps stress wave transverse to the ground more effectively and efficiently,

JCB to introduce new engines at bauma 2013

JCB is presenting its Ecomax engines for the first time at bauma 2013. These engines meet the rigorous emissions standards Stage IIB and Tier 4 Interim, without the need for diesel particle filters or emissions after-treatment.

JCB secures new engine supply deal

JCB announced it had signed a long-term agreement to supply engines for a new range of rotating telescopic handlers to be launched by an Italian manufacturer. MAGNI Telescopic Handlers, headed by Riccardo Magni,

Earthmovers on buoyant swell

Earthmoving equipment currently constitutes nearly 73 per cent of total construction equipment sales, and happily, this structure of sales is expected to continue. The cumulative sales of backhoe loaders, crawler excavators and wheeled loaders have been growing at a CAGR of over 20 per cent for the last ten years.

We keep our customers at the heart of all our initiatives and endeavour.

JCB has recently announced its plan to set up its fourth world class manufacturing facility on a 70- acre site in Jaipur. The approximate investment of Rs 500 crore has been planned to set up this facility in phases. Our idea is to keep pace with future economic growth and strengthen our position as market leader in the construction equipment industry both in India as well as APAC & MEA, says Vipin Sondhi, Chief Executive Officer & Managing Director, JCB India. Excerpts from the interview.

JCB manufactures products which are robust, custom built and highly fuel-efficient.

JCB offers a world class vibratory soil compactor VM115 and a recently launched 9 T Tandem Roller VMT 860, which are specifically used for road projects. These machines are built specially for Indian roads and are amongst the best at compaction, says Amit Gossain, VP - Marketing & Business Development, JCB India. Excerpts from the interview.

Fuel and Energy Efficient Machines

In an intensely competitive market, OEMs are no more just technology providers; rather, they are keen on providing total solutions specific to a project.

The all-new JCB 3DX

With the launch of the new 3DX backhoe loader, JCB plans to strengthen its share of the backhoe loader market in India and extend its reach even further to the developing rural markets.

JCB gives utmost importance to safety and our tracked excavators are the safest choice

All JCB excavators are fitted with a unique filtration system which increases hydraulic oil and filter life resulting in huge cost savings and better emissions.

JCB offers the widest range of backhoes covering all applications and terrain

Our range of backhoe loaders are equipped with the fuel efficient and reliable ecoMAX engine, in-house durable axles and transmissions, best- in- class hydraulic forces, all of which result in superior loader and excavator performance, long lasting structure, says Amit Gossain, Vice President Marketing & Business Development, JCB India. Excerpts from the interview.

JCB always keeps customers at the heart of everything it does

?We focus on both process innovation as well as product innovation. We have dedicated teams working on each of our product lines with the sole purpose of increasing efficiency through value engineering," says Vipin Sondhi, Managing Director & Chief Executive Officer, JCB India.

With 55 dealers and over 410 outlets, we have the best support network

Our initiatives and activities are very focused on the heavy range of equipment viz, tracked excavators, soil and asphalt compactors and wheeled loaders. We have functional factories, focused manpower and after-sales support personnel for

Compacting Technology Set to Improve

The new trend in technology is faster compaction by achieving the required density at a lower operating cost. Also, the latest equipment is designed with features to improve operator safety, comfort and maintainability.

We have doubled our distribution outlets over the last five years

With strategic investments in place, we have the right kind of facilities and can upscale our production whenever required, says Vipin Sondhi, Managing Director & CEO, JCB India,

Engines of Growth

A recent report from the United Nations Industrial Development Organisation (UNIDO) forecasts that the world's manufacturing output growth will be slower compared to the last year. As per the report, the developing countries have maintained high growth rates of manufacturing with production increasing by 11.1 percent.

Engines of growth

Studies show that at present as per 2010 figures, diesel engines in India emit a total of 357,959 tonne of pollution. If we were to use diesel engines with lower emissions, then this figure would be reduced to 116,325 tonne. Couple this with the fact that there are over 400,000 diesel powered vehicles being produced every year and 250,000 diesel powered gensets

JCB is numero uno in backhoe loaders worldwide

JCB's backhoe loaders are the machines that promise versatility and high performance with their fuel-efficient engines and superb manoeuverability.

JCB - The Numero Uno

JCB's backhoe loaders are the machines that promise versatility and high performance with their fuel-efficient engines and superb manoeuverability.

EcoMAX is optimised for JCB construction equipment to offer maximised fuel efficiency

The JCB engine ecoMAX is on the same platform as the JCB Dieselmax, the record breaking engine that powered the car which holds the world's land speed record, says Vipin Sondhi, Managing Director and Chief Executive Officer, JCB India. 0 - - 16072 14 188 2011-06-01 00:00:00.000 Equipment India Volvo-Srei BNP Deal

Volvo India and Srei BNP join hands to launch Volvo Financial Services.

Volvo India and Srei BNP Paribas have announced the formation of an alliance to launch a private label retail financing programme branded as Volvo Financial Services in India with immediate effect. This will strengthen the Volvo Group's ability to provide full service financial solutions to Volvo Group customers in India and customers of its joint venture (JV) with Eicher Group, viz, VE Commercial Vehicles Ltd (VECV). With the launch of the Volvo Financial Services offering, the Volvo Group will accelerate its business growth in India across all of its products by packaging its product offerings with financing through its alliance with Srei BNP Paribas. By engaging the two companies at the sales, marketing and operations levels, the alliance will allow both companies to address new growth opportunities by developing co-branded financing programmes and services for customers of the Volvo Group and Srei BNP Paribas.

Being a part of the Volvo Group, Volvo Financial Services in India is aimed at building a reputation for attractive customer financing services to the external and internal customers of the Volvo Group and VECV. Volvo Group's brands include Volvo trucks, Volvo construction equipment and Volvo buses, while VECV's brands include Eicher trucks and Eicher buses. Srei BNP Paribas is India's largest construction equipment finance company and with this alliance, Volvo Financial Services will leverage Srei BNP Paribas's expertise of over 22 years coupled with a network of 87 offices across India, strong underwriting capabilities and an asset base of over Rs 12,000 crore to increase its penetration and give complete financing solutions to customers buying Volvo products in India.

John Rakocy, President of Volvo Financial Services for Region Asia/Pacific comments, ?After a comprehensive review process, we are excited to ally with Srei BNP Paribas for Volvo Financial Services in India. The Volvo Group and its distributors will benefit from leveraging Srei's expertise and financial capabilities in credit underwriting, funding, and sales and marketing effectiveness through a private label programme under the Volvo Financial Services name. We look forward to continued growth within this key Asian market.?

D K Vyas, CEO, Srei BNP Paribas, says, ?We have a partnership approach in all our businesses and we are happy to join hands with Volvo Financial Services, in their endeavour to provide financing solutions to Volvo Group customers. We have been financing Volvo Group products since their entry into the country but through this formal association, we will complement each other's strength and further cement our relationship. Srei BNP Paribas' dominant leadership in this business, consistency, innovative financing products, and its distribution should help the Volvo Group increase its market share and participate in the India growth story.?

Volvo Financial Services is the global finance arm of the Volvo Group. The Volvo Group is one of the world's leading manufacturers of trucks, buses and construction equipment, drive systems for marine and industrial applications, aerospace components and services, and is the world's leading producer of heavy-diesel engines (9-18 litre). Volvo Financial Services was formed in 2001 and is headquartered in Greensboro, North Carolina, USA. The company has assets of over $14 billion, more than 1,200 employees worldwide, and conducts business in over 40 countries across Asia-Pacific, Europe and the Americas. Volvo Financial Services provides a full range of financial services for the truck, construction equipment, bus, marine, and aerospace industries. The primary brands that Volvo Financial Services supports are Mack Trucks, Renault Trucks, UD Trucks, Volvo Trucks, Volvo Construction Equipment, Volvo Buses, Volvo Penta, and Volvo Aero.

The alliance will strengthen the Volvo Group's ability to provide full service financial solutions to Volvo Group customers in India.

Construction , Update , Portal , Magazine , Equipment India , 2011 , June , 2011 , Volvo India , Srei BNP , Volvo Financial Services , retail financing , Volvo Group , Eicher Group , John Rakocy , D K Vyas , Greensboro , North Carolina , USA 0 2011-06-16 11:27:34.333 22 Volvo India and Srei BNP Paribas have announced the formation of an alliance to launch a private label retail financing programme branded as Volvo Financial Services in India with immediate effect. 1 - - 16073 14 94 2011-06-01 00:00:00.000 Equipment India WILL THE DOMINANCE CONTINUE?The invention of backhoe in the early 50s by Joseph Cyril Bamford changed the face of construction across the globe. From a historic perspective, the growth of backhoe loaders in India has happened at the cost of mini excavators and mobile excavators; mainly on account of the first mover advantage. The affordable price and multi-application versatility made backhoe a popular machine. Even though the global trend shifted towards specialised equipment, in emerging markets like India which is slowly moving towards the same trend of usage of specialised equipment and attachments, backhoes still dominate the sale.

As per the data collected by Equipment India, India is the world's largest backhoe loader market with over 30,000 units expected to be sold in FY 2011-12. This momentum is expected to continue with the increased spending on infrastructure development. No wonder, many domestic and global OEMs have entered this market segment, and have augmented the capacity. JCB invested during the downturn to upgrade its backhoe facility to the world's largest backhoe manufacturing plant with a capacity to build 100 machines per shift. Escorts is doubling the capacity for its Digmax; Mahindra & Mahindra which has recently forayed into this segment has built a capacity of 2,000 units per year; Terex has a production capacity of 2,500 machines per annum, that can be ramped up as per demand; ACE also is in the process of doubling the capacity to over 4,000 units per year. As per inputs, the first quarter of CY2011 has seen a robust growth of 40 per cent over last year. Though the market has seen a slight slowdown due to the implementations of BS III regulations, the overall backhoe market will grow by another 15 per cent this year.

But how long backhoe market will be able to dominate?

Three different reasons: firstly, the shift towards specialised equipment for speicalised jobs; secondly, the wheel loader market is getting more and more aggressive, especially below 10T class; thirdly, the high possibility of an expanding market for mini excavators.

As Indian government is pushing for higher investments for the development of infrastructure, more and more global players are establishing their base in India to exploit the opportunity. This has led to tremendous competition and benefitted the customer with enhanced quality and better performance on the offer. One noticeable trend is the India-centric design of machines, and efforts put into the continuous improvement of machines as per the feedback from the customers. Major players extensively use consumer insight and feedback to further develop the product which is built to withstand India's rough terrain and heavy usage patterns. In addition, most of the players offer products with cutting-edge features using the latest vehicle systems and technologies at prices that are within the reach of the mass market. More importantly, there is more

and more emphasis on service, and no wonder, most of the OEMs are investing on service and spare network to reach the customer as fast as possible.

The earthmoving segment is driving the overall industry with strong demand emanating from the government-backed infrastructure projects. The segment is poised for an unprecedented CAGR of around 18 per cent during FY 2011- FY 2014, as per a research report from Putzmeister.

The outlook for India's construction industry remains largely unchanged between the financial years of 2010-11 and 2011-12 and the growth tandem would remain same till fiscal 2015-16. This relatively high growth figure indicates that there are a large number of projects available to the infrastructure companies throughout the country in the forecasted period. The research sees certain sectors, such as the power and airport sectors, presenting more growth opportunities than others. However, there are significant risks preventing the realisation of returns for these projects and these risks are inhibiting upside movement to our construction growth forecast.

The latest statistical data from India's Ministry of Statistics and Programme Implementation show that the real growth for the Indian construction industry reached 9.6 per cent year-on-year for April-September 2010. While this suggests that there is upside potential to the FY 2010-11 construction forecast, The report is maintaining the projections due to persistent concerns about the sector's ability to filter investment through the intended projects. Among these concerns, India's nebulous business environment remains the most pertinent.

The forecast

Even though India is experiencing a slower growth rate due to the current economic downturn, it is expected to rise again within the next three to four years thanks to its resilience to the world markets' conditions. The growth rates forecasted for the construction industry sectors will exceed the overall GDP growth. The commercial and industrial construction sectors are growing at an annual rate of approximately 10 per cent, compared to 6-7 per cent for residential construction.

Spike in construction industry growth

Rapid growth in the construction sector is creating enormous sales potential for manufacturers of construction machinery. The increase in sales of earthmoving equipment by 17 per cent and construction vehicles and mining equipment by 53 per cent demonstrates the immense potential for all sectors of the construction industry.

Construction equipment

World's seventh largest country by area and second biggest by population makes India one of the most dynamically growing and still, largely untapped construction equipment (CE) industry. The country has witnessed massive investment in the construction industry from both public and private enterprises in recent years. Multi-billion dollar investments made in constructing roads, ports, power plants, telecommunication sector, urban infrastructural developments, etc, have paved the way for construction equipment demand to grow substantially in recent years.

According to research report from Putzmeister, the CE industry in India has witnessed consistent double-digit CAGR growth over the past few years. The global economic slowdown had its moderate effects on the industry, but it regained growth momentum in FY 2010 and showed positive year-on-year growth. Particularly, the earthmoving segment is driving the overall industry with strong demand emanating from government-backed infrastructure projects. The segment is poised for an unprecedented CAGR of around 18 per cent during FY 2011?FY 2014.

Over the last 3-4 years, various new entrants made inroads in the Indian CE industry. Some of the biggest names belong to Japan, the US and Korea. Besides, a number of domestic companies are either expanding their domestic capacities or diversifying their product portfolio. With the emergence of new market players and expansion plans underway, the industry is expected to become more competitive and fragmented. However, these new capacities will find their home quite comfortably in the domestic market amid growing mechanisation and proposed large infrastructural projects.

The report provides profound research and rational analysis of the Indian CE industry. It provides information/statistics of all prominent market segments including earthmoving, material handling, concrete equipment and road building equipment. Analysis of past, present and upcoming industry trends provide balanced market intelligence on the concerned industry. In addition, we have covered key industry players and their business description to examine industry's competitiveness and growth potentials.

As per the report, there are five trends that will shape the evolution of the industry and highlight the imperatives to realise this opportunity. Of these, four are growth opportunities ? investments of $750 billion in infrastructure development; the increasing dominance of price-and-value-focused customers; deeper engagement of global equipment manufacturers in India; and increasing opportunities for exports. However, the trend of increasing competition from product imports from other low-cost countries like China could potentially challenge the industry growth and is forced that players need to address proactively.

Conservative estimates suggest that 'as usual' growth will create a market of $8 billion by 2015. But a concerted push by the industry and government alike could result in an additional $4 billion opportunity, equally split between exports and the provisioning of India-specific products.

A study says, for the industry to achieve its full potential, players need to embark on three strategic initiatives ? (i) introduce India-specific products that include introducing low-priced multi-purpose equipment to attract new customers and to increase mechanisation in important areas, adding features to products that make suitable for use in India and launching new applications and products for missing applications; (ii) improve cost positions to better deal with the onslaught of competition from LCCs; and (iii) pioneer efforts to boost exports in areas like engineering and design services that leverage India's technical prowess.

In addition, companies need to pursue four growth-enabling initiatives to expand the market. These include enhancing the quality, delivery and price of after-sales services to increase the share of service revenues from 2 per cent of total revenues to the global average of about 8 per cent; addressing key gaps in financing to catalyse latent demand particularly in rural areas and small towns; expanding dealer and channel network coverage to address buyer fragmentation and quality and proactively strengthening supplier capacities and capabilities.

Construction equipment players have a unique opportunity to help realise the potential of this sector and, in doing so, garner their share of the $12-13 billion revenue potential.

The Indian economy:

? More than EUR 140 billion invested in energy and infrastructure.

? Construction-industry growth rate is higher compared to the overall growth rate in India.

? Ten per cent expected annual growth for commercial and industrial construction (2010-15)

? Indian economy quickly regains the momentum.

Industry trends:

? Investment of $750 billion in infrastructure.

? Increasing dominance of price-and-value-focused customers.

? Deeper engagement of global OEMs in India.

? Increased opportunities for exports.

? Increased competition from product imports from LCC.

Infrastructure investments:

? India has one of the world's biggest purchasing power and ability to attract large investors from all over the world. Investments in various infrastructure sectors are projected to reach impressive EUR140 billion in 2010:

? EUR 100 billion for the energy sector.

? EUR 17-21 billion for road construction.

? EUR 5.7-7 billion for ports

? EUR 10.7-14.3 billion for airports.

?Mahindra & Mahindra has entered the construction equipment business with Mahindra EarthMaster backhoe loader. In the next 3-4 year, Mahindra Construction Equipment division would have full range of construction equipment,? says Kairas Vakharia, Senior Vice President and Business Head, Mahindra Construction Equipment Business. Excerpts from the interview.

Mahindra is the latest entrant in the highly competitive backhoe segment. How do you look at the present scenario of backhoe market?

India is the world's largest backhoe loader market with over 30,000 units expected to be sold in FY 2011-12. This momentum is expected to continue with the increased spending on infrastructure development. However, the backhoe loader customers have become more demanding in terms of getting more value from the investment made in their equipment. Mahindra intends to make a strong foothold in BHL market by offering Mahindra EarthMaster with a host of benefits/features which are unheard of in this industry. This will help our customers break-free from old technology and enable them to ?rise'.

Tell us about the response Mahindra has received after the launch of EarthMaster?

There has been a tremendous response for Mahindra EarthMaster. We have been doing demonstrations of Mahindra EarthMaster pan India and there is a very positive wave among customers regarding the various unique features it offers to customers. Some of the features that are most appreciated are high fuel efficiency of Mahindra DITEC engine, Remotecare, crawler excavator like hydraulics, fatigue-free joystick operations, stylish cabin and two years of unlimited hours warranty. All of these features are new for backhoe loader customers.

What is the existing manufacturing capacity for backhoes?

The Mahindra EarthMaster is manufactured at our state-of-the-art facility at Chakan, Pune. The current production capacity of the plant is 2,000 units per annum which can be easily ramped up.

Which segment contributes to the maximum share for backhoes in India?

The hirers constitute the largest segment with more than 50 per cent market share.

What differentiates Mahindra from competition?

Mahindra's Product Development team has utilised extensive consumer insight and feedback to develop this product which is built to withstand India's rough terrain and heavy usage. In addition, the product offers cutting-edge features using the latest vehicle systems and technologies at prices that are within the reach of the mass market.

Are these products complying with emission norms Bharat Stage III?

The Mahindra EarthMaster is powered by Mahindra's DITEC Engine, a compact 3.3-litre engine which delivers best-in-class 83 HP (Ps) power. The DITEC engine is packed with the latest technology for minimising emissions that meet BS3 and also USA Tier III emission norms, the most stringent in the world. The construction of the DITEC engine combining Direct Injection (DI) with Turbo Charger and Intercooler (TCI) delivers over 10 per cent fuel savings per hour.

Tell us about your strength in providing training and service network in India?

The company has put in place a dedicated sales and service network to cater to its construction equipment customers. This will include over 200 dealer sales, service and spare part outlets, over 200 service vans to reachout to the customers at their sites, 12 area offices, one central parts warehouse and 10 regional parts warehouses to supply dealers and a call centre supporting nine languages. We also have a dedicated training set-up for training machine operators/technicians.

?Terex backhoes perform faster while digging and loading at lower operating costs, with durability through quality and technology innovation,? says Vijay Sharma, Executive Director, Terex Equipment. Excerpts from the interview.

What is the demand-supply scenario for backhoes in India? What is Terex's market share in backhoes, and growth envisaged?

We don't see any demand-supply gap in India at present. The first quarter of CY2011 has seen a robust growth of 40 per cent over last year. However, since the implementations of BS III regulations, the market has seen a slight slowdown. Still, we believe that the overall loader backhoe market will grow by another 15 per cent this year. We strongly believe that this trend should persist for another couple of years before stabilising henceforth. In terms of value, there does not seem any major jump as Indian customer still believes in value for money concept and is still not ready for paying higher for enhanced features in machines. As far as Terex is concerned, we are growing at a steady pace and hopefully, we should be able to achieve double digit market share in another couple of years.

The various factors, which will enable this sound growth for coming times, are mainly government's continuous focus on development of infrastructure by pumping and inviting more and more investment, better credit facilities and preference of Indian customer for Made in India brand of backhoe loaders.

Tell us about the range offered by Terex?

The new range of backhoe loaders ? TLB 740S with 76-hp Kirloskar engine and TLB 844S with 90 hp Kirloskar engine - is a result of continuous up-gradation in innovation and technology. In compact loader segment, we manufacture HEMAN 175 skid steer loader, having option of 65-hp or 80-hp engine, making us the only local manufacturer in this space in India. This machine, which has more than 50 standard attachments, is more like an engineering marvel. Further enhancing its product offering to Indian customers, Terex recently introduced RL 4000 light towers, which addresses the requirement of construction houses and builders to work efficiently even during night time.

Tell us the unique features of backhoes offered by Terex?

Terex backhoes perform faster while digging and loading at lower operating costs, with durability through quality and technology innovation. Highlights of this product are fuel efficiency through unique Smart UC Hydraulics. These products have been developed in India for Indian market from application and maintenance points of view. These machines are almost completely indigenous. Tougher, stronger structural parts such as boom and dippers, heavy-duty stabilisers with adjustable wear pads have been introduced to achieve longer service life than competition in Indian tough applications. Improved protected hose routings and other hydraulics are designed in segments to achieve lower replacement costs and longer uninterrupted working.

What is the existing manufacturing capacity for the backhoes?

At present, we have a production capacity of 2,500 machines on annual basis. However, foreseeing the tremendous potential and opportunity available in future, we may plan to ramp up our capacity to address the increasing demand for our products.

Which segment contributes the maximum share for backhoes in India?

According to our estimates, major chunk of the industry is contributed by first-time user/first-time buyer segment. This segment accounts for nearly 50-55 per cent of the total industry followed by retail/repeat buyers (25-30 per cent) and corporate customers (15-25 per cent).

What is the rental scenario for these products?

The rentals are more or less stagnant over the least 2-3 years. This is mainly due to increased number of machines available in the market. However, the rentals are also dependent on the topography of the region, ie, in hilly terrains; the rentals are always 20-25 per cent higher than the rentals in plain areas. We also consider it very seriously that with the entry of big rental companies, the rent would go up in near future.

What is the return on investment on a backhoe?

At present, due to enhanced competition among backhoe owners, the rentals have been stagnant in spite of increase in owning and operation cost over the last few years. Hence, it has affected the return on investment for these machines. Nowadays, we can safely assume that an average customer is able to recover his investment in 3-3.5 years, which used to be 2-3 years in the past.

Tell us about the attachments offered along with backhoe?

Nowadays, the main attachments being offered with backhoe loader machines are rock breaker, 6-in-1 shovel, ditch cleaning bucket, and trenching bucket etc.

How do you look at the competition in this segment, and what differentiates Terex from competition?

As Indian government is pushing for higher investments for the development of Indian infrastructure, more and more global players are establishing their base in India to exploit the opportunity. This has led to tremendous competition and benefitted the customer with enhanced quality and better performance on the offer. Terex is also on the threshold of becoming a serious player in this space. We offer world-class technology at the customer's doorstep and that too at an affordable price. Our products comprising backhoe loader, skid steer loader, wheel loader and light tower are continuously setting higher benchmarks in terms of reliability and productivity. More and more customers are becoming our repeat buyers on account of value for money proposition products are being offered.

Are these products complying with emission norms Bharat Stage III?

Of course, all our products are BS III compliant. Perhaps it is a blessing in disguise for us as our machines have become more fuel-efficient and environment-friendly.

Tell us about the footprint created in India. What are your plans on expanding dealer network, service stations etc?

Terex Equipment, even though being a new entrant in Indian CE industry, has been able to establish a vast distribution network all across India and neighbouring nations. The company has 49 committed dealers who sell, service and provide parts round-the-clock with the help of a workforce of over 600 trained engineers and technicians. However, as we see a spurt in demand for Terex products in coming times, we are continuously enhancing our distribution network which includes adding branches to existing dealerships as well as appointing new dealers at strategic locations.

To what you attribute the success Terex has registered so far?

The success of Terex in India can be attributed to the two main factors ? excellent work environment at our workplace and indelible trust of our customers. We recognise that to accomplish our goals, we need diverse perspectives and inclusive work environments that enable us to attract, develop, motivate and retain the very best people. We believe that being a great place to work means creating the kind of workplace where great people can do great things.

Diversity at Terex is about respecting and embracing more than our tangible differences, like gender, ethnicity, national origin and race. We value diversity of thought, experience, culture, background and style. It is those unique characteristics that make each Terex team member a vital contributor to our competitive advantage. We celebrate that each and every one of our team members brings something unique and beneficial to our workplace. Due to these attributes, we are able to roll out the best machines in terms of reliability and performance which eventually wins the trust of our customers.

Construction , Update , Portal , Magazine , Equipment India , 2011 , June , 2011 , Vijay Sharma , Terex Equipment , BS III regulations , infrastructure , investment , backhoe loaders , Kirloskar engine , engineering , Smart UC Hydraulics , ditch cleaning , government 0 2011-06-16 12:30:21.273 22 Terex backhoes perform faster while digging and loading at lower operating costs, with durability through quality and technology innovation," says Vijay Sharma, Executive Director, Terex Equipment.

JCB launches ecoMAX

JCB India announced the launch of its own domestically built world-class, fuel-efficientBSIII, 16-valve diesel engine to power its equipment range progressively.

ecoMAX debutes in India

JCB launches the world-class fuel-efficient JCB engine ecoMAX. At JCB India's Ballabgarh facility, approximately 40,000 engines will be produced annually, starting April 2011.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com